Description

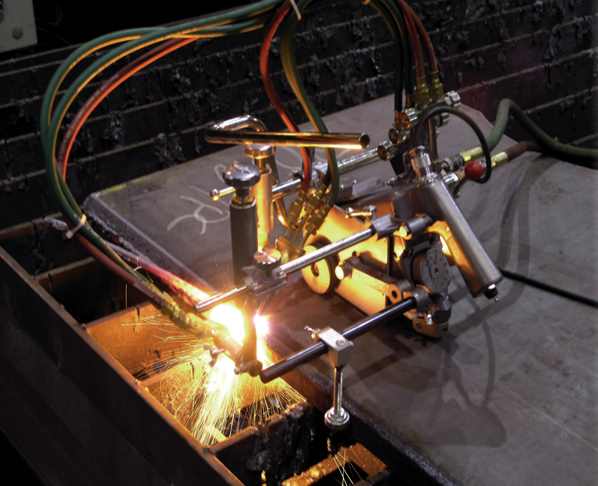

The IK-93T Edge-Cut is a double-torch, trackless plate edge bevelling machine that performs sharp bevel cuts.The machine is equipped with two specialized torch units each with a gradated angle indicator, which ensures accurate torch angle settings.

Features

- Trackless

bevelling

Bevels plate edge top and bottom, up to 45˚ without need for track. For V, X, Y, and K bevel welding preparation on the edge. - Pre-set

flame

Unique Koike preset stop valve allows saving flame settings and quickly turns gases on and off. - Pistol shape

grip

Operator can control forward / reverse, clutch and speed adjustment with just one hand. - Compact and

lightweight

Although the machine is equipped with two torches and gas unit, it only weighs 12 kg, machine can be moved from one plate to the other easily. - Multi

purpose

By removing caster on the bottom of the machine, straight cutting can be done by use of rail.

Technical specifications

| SPECIFICATIONS IK-93T Edge Cut | |

|---|---|

| Cutting thickness | 5-50 mm |

| Cutting speed | 100-1000 mm/min |

| Bevel angle | 0 ~ 45º |

| Clutch | Trigger type mechanical clutch |

| Speed control | Control IC |

| Heat shield | Double shield for thermal protection |

| Input power | AC 42V |

| Dimension (excl.torch unit) | L380 x W130 x H210 mm |

| Weight | 12 kg |