Description

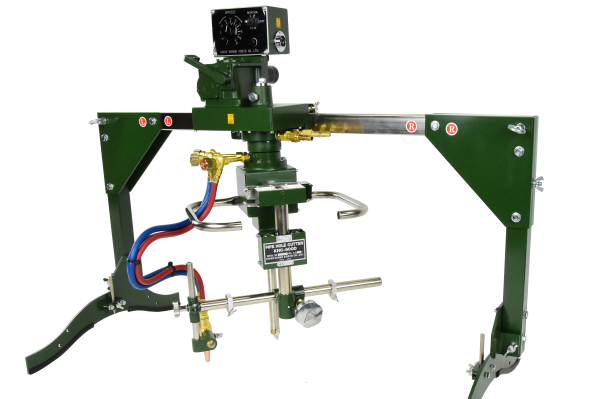

KHC-600D is ideally suited for cutting high precision T- joint circles including any hole that crosses the side of the pipe for piping systems, high pressure vessels and heat exchangers. Developed with Koike Advanced Technology, the KHC-600D is a compact design that is light weight and easy to operate.

In addition to cutting circles and bevel in flat plate, the machine can cut a vessel from the inside or outside.

Features

- Automatic oxy-fuel pipe

cutter

Automatically bevel cuts or straight cuts holes into pipe. - Infinite rotational gas

manifold

Tangle-free, infinite rotation gas manifold eliminates tension to the torch during cutting, ensuring accurate, sharp & clean cuts. - H-lever

handle

Torch height is automatically maintained to work distance based on trigonometry function of H-lever; very easy setup with just two adjustments. - On/Off drive clutch

- Flat plate circle

cutting

Can be used for circle cutting on flat plate.

Scope of delivery

Technical specifications

| KHC-600D | |

|---|---|

| Cutting thickness | 5 - 50 mm |

| Torch rotation speed | 0.12 ~ 1.2 rpm |

| Cutting diameter | ø 80 ~ 600 mm |

| Torch up/down stroke | 0 ~ 100 mm |

| Torch revolving radius | r 40 ~ 300 mm |

| Bevel angle | 0 ~ 45º |

| Speed control | Control with dial operation |

| Pipe ration branch: main | 1:2 and above |

| Input power | AC 115V / AC 42V |

| Dimension | L1050 x W500 x H760 mm |

| Weight | 26 kg (incl. support leg) |